3D scanning is crucial for product development, enabling designers to create precise digital models of physical objects. It quickly captures an object’s shape and dimensions, making digital versions easy to modify and refine. 3D scanning is also vital for reverse engineering. Designers can scan existing products to understand their structure, which helps create replacement parts or develop products that fit with existing components.

“3D scanning is like taking a photograph of an object, but instead of capturing just its surface appearance, it captures every detail, curve, and nuance in three dimensions, allowing for endless possibilities in product development and design.”

Founder and CEO – Rodrigo Lima

At the start of any project, it’s crucial to examine the requirements. This helps determine the necessary tools and technologies. For product development, 3D scanning is one potential tool among many. We evaluate if 3D scanning is needed based on several factors, including object complexity, required precision, available resources, and project timeline. If 3D scanning is necessary, we use our state-of-the-art equipment to capture high-quality surface details of the object.

There are several types of 3D scanning techniques, each with unique strengths and weaknesses. Structured light scanning captures detailed surface information on smaller objects. Time-of-flight scanning suits larger objects and environments, quickly capturing extensive data. Laser scanning provides high-precision data for industrial and engineering applications. Photogrammetry creates 3D models of large outdoor environments using a standard camera. The choice of scanning technique depends on project-specific needs. These include object size, complexity, desired detail level, and available resources. After scanning, the model still requires some refinements.

After 3D scanning, the result is typically a point cloud. This represents the object’s surface as individual points in 3D space. The point cloud data must be processed and converted into a mesh of interconnected polygons. The resulting mesh may contain errors like holes, spikes, or self-intersections. These can cause problems in design or manufacturing. To fix these issues, we use mesh cleaning software to refine and correct the model. The cleaning process involves various techniques. These include smoothing, filling holes, removing unwanted vertices, and optimizing the mesh structure.

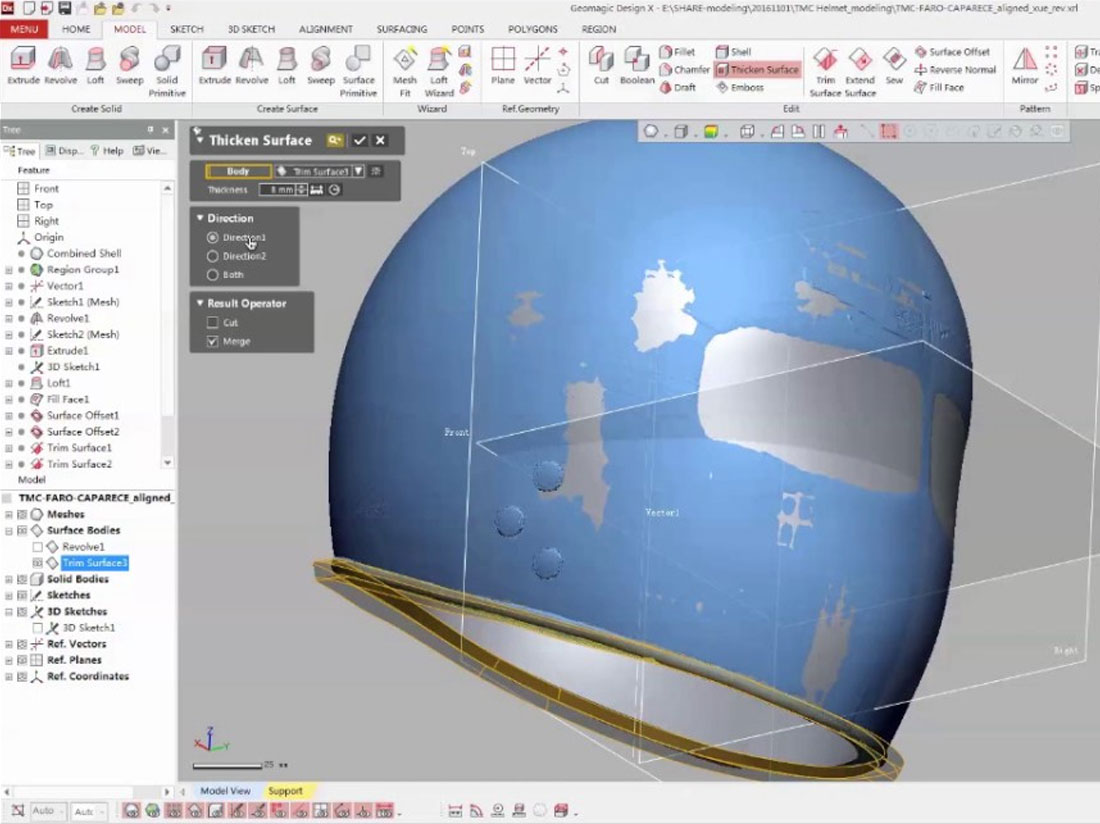

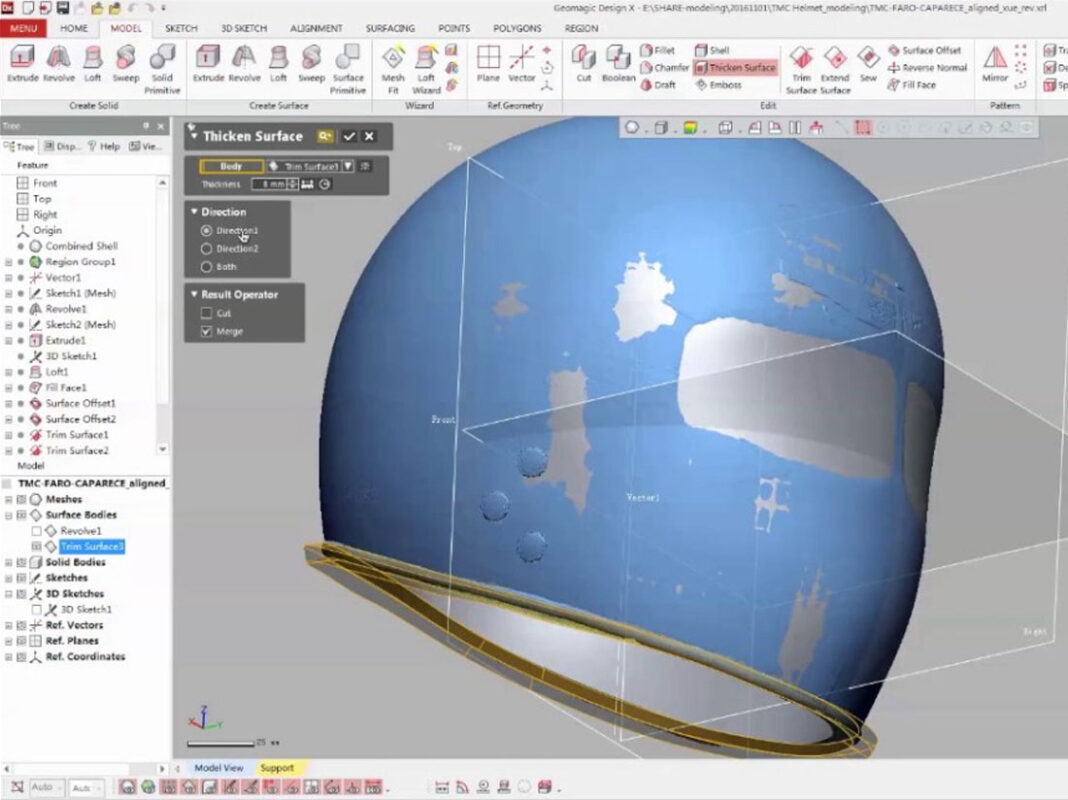

After 3D scanning and mesh conversion, our engineers use the mesh as reference geometry. They build a 3D model on top of it, using it as a guide for shape and dimensions. However, the mesh may not suit all applications, especially when high precision is needed. In such cases, engineers may create a new mesh to match desired specifications. Using the mesh as a reference ensures an accurate and precise final 3D model. It maintains the original object’s shape and characteristics. This process is crucial for creating high-quality products that meet client needs.

3D scanning is crucial in product development. It captures precise digital representations of physical objects. This enables accurate measurements and swift prototype iterations. It reduces time-to-market and minimizes costly errors. 3D scanning streamlines production, enhances quality, and helps deliver innovative solutions that exceed consumer expectations.

3D scanning captures the shape, size, and texture of real-world objects or environments. It uses specialized hardware and software. The process emits light or laser beams onto the object. It then measures reflected signals to create a point cloud representing surface geometry. This point cloud is processed into a digital 3D model for various applications.

Various 3D scanning machines cater to different needs. Handheld scanners like the Artec Space Spider offer portability. They’re suitable for on-site scanning of intricate objects. Larger stationary scanners are used in industrial settings. These prioritize precision and speed for capturing large-scale objects or environments accurately.

Are you an inventor with a groundbreaking idea, but unsure of how to turn it into a reality? Look no further! Our product development firm specializes in partnering with inventors like you to bring innovative concepts to market.

Let us be your trusted partner in transforming your vision into a tangible product that revolutionizes the market. Contact us today to schedule a consultation and take the first step towards making your idea a success!

Thank you for showing interest in Lime Design, you can fill out the contact form below and tell us a little about your project and we will contact you to setup a discovery meeting to give you an accurate quote.

Upon completing this form you will be emailed an NDA (mutual non-disclosure agreement), please sign it as soon as you can.

English, Spanish, Portuguese

Copyright @ 2008-2023 | All Rights Reserved | Terms & Conditions

English, Spanish, Portuguese

Copyright @ 2008-2023 | All Rights Reserved | Terms & Conditions