Sourcing the right manufacturer for your product can be a challenging task that requires careful research and evaluation. With so many manufacturers to choose from, it’s easy to become overwhelmed and make the wrong decision. However, we make it easy for you by providing established sourcing partners that eliminates the hassle of finding the right manufacturer for your product. We take the guesswork out of the process, saving you time and money in the long run.

“Sourcing is like searching for a needle in a haystack. It can be overwhelming, time-consuming, and frustrating. But with the right team, we can help you successfully manufacture your product.”

Founder and CEO – Rodrigo Lima

At Lime Design, we have a large resource of manufacturing partners overseas all with a signed NDA so your product is safe. We have been working with all of our partners for several years and have successfully produced hundreds of products together. One of the biggest advantages to having partners ready is that we can quickly explain your project to them and begin getting quotes. We start our conversation with them by sending all of the files we have created for your product. This includes drawings, specifications, and any other relevant documents. Once the manufacturers have reviewed your files, they will be able to provide you with a detailed quote that outlines the cost, timeline, and other important information related to the project.

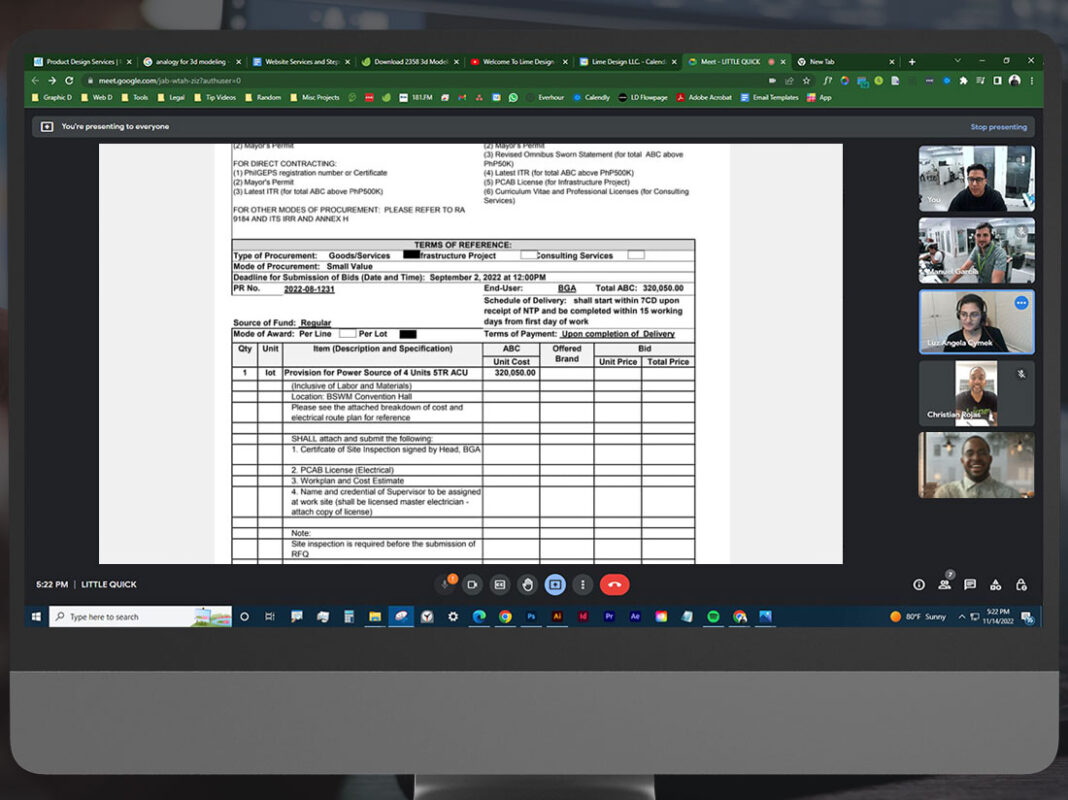

After we receive the estimates from multiple factories, we carefully review, evaluate, and negotiate the project with the factories to produce the best quotes possible. This includes not only the cost but also factors such as the quality, lead time, and communication. Through effective communication and a deep understanding of the manufacturing process, we are able to negotiate on your behalf to achieve the best outcome for your project. We can reduce costs by using different materials or reducing certain options to optimize your product. Once we have chosen the best options, we then set up a meeting with you the client to review the estimates from all factories interested.

The next step is to carefully review and evaluate each proposal to determine the best option for your project. It is important to review the proposals in detail to ensure that all of your requirements are met and that there are no hidden costs or surprises. Once you have evaluated each proposal, you can make an informed decision on which factory to work with based on your specific needs and budget. Our team can assist you with this process, providing expert guidance and advice to ensure that you make the best choice for your project.

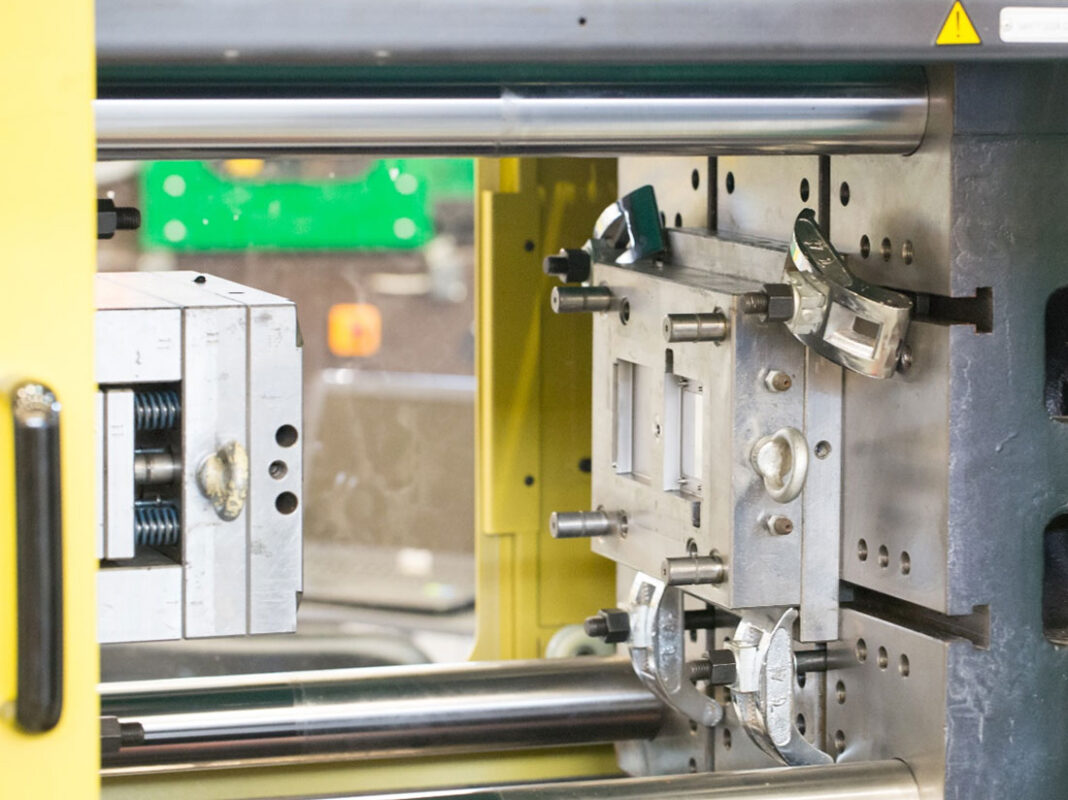

After selecting a manufacturer, we facilitate the introduction between the client and the manufacturer to begin their working relationship. Our team acts as a liaison to ensure that both the client and manufacturer are on the same page and that the production process runs smoothly. We can remain involved throughout the entire process, providing ongoing support and assistance to ensure that the final product meets the client’s expectations. Typically every product requires a mold and depending on the complexity may require multiple molds. So the next step would be to make the payment for the required molds so that the factory can begin producing off-tool samples.

Before the production process begins, the manufacturer will typically produce a set of off-tool samples known as T-0 samples. These samples are the first physical samples produced using the production tooling and processes. It typically takes a month or two to produce T-0 samples, as the manufacturer needs to ensure that everything is working as expected and make any necessary adjustments. Once the T-0 samples are received, our team can help review the samples to document and note take any refinements that may be required. This process continues with a T-1 sample and so on for as many rounds as needed. Typically their needs to be about 1-3 rounds of sampling before we can approve the product for mass production.

Once the off-tool samples have been reviewed and approved, the factory can move on to mass production of the product. This involves scaling up the production process to meet the desired volume of units. The manufacturer will work closely with the client to ensure that the production schedule and timelines are met. During this phase, it is important to maintain communication with the manufacturer to ensure that the product meets the desired specifications and quality standards. Our team can remain involved throughout the entire production process, providing ongoing support and assistance to ensure that the final product is delivered on time, within budget, and to the highest quality standards.

During the production process, it is important to have a level of quality control to ensure that the final batch of products meets the client’s standards. The manufacturer can provide this quality control, typically through a series of inspections and testing procedures. This includes checking for defects, verifying the specifications, and ensuring that the product meets any regulatory requirements. Our team can also conduct our own inspections and quality control procedures to ensure that the final product is of the highest quality. Through effective communication and collaboration with the manufacturer, we can ensure that the production process runs smoothly and that the final product meets the desired standards.

Once production is complete, the next step is to ship the products to the client. This involves determining the most cost-effective and efficient shipping method that meets the client’s budget and time requirements. Our team can work closely with the client to evaluate the available shipping options and recommend the best approach based on the client’s specific needs. This includes considering factors such as the size and weight of the products, the destination, and the desired delivery timeline. Our goal is to provide a seamless shipping experience that meets the client’s expectations and ensures that the final product arrives on time and in excellent condition.

Choose your path and either decide to go down the path of Manufacturing or Licensing your product. If you want to pursue manufacturing, we will prepare a proposal for 3D modeling, engineering, prototyping, and manufacturing for your product. If you want to pursue licensing, we will prepare a proposal for us to help you create marketing tools such as 3D modeling, animation, and presentations – which will help give you the tools to license your idea or try to raise funding from investors to further develop your idea.

Manufacturing sourcing is crucial in product development as it directly impacts product quality, cost, and scalability. By carefully selecting manufacturing partners, companies can ensure that their products are produced to the desired specifications and standards. Additionally, effective manufacturing sourcing facilitates cost optimization, supply chain management, and timely delivery, enabling businesses to meet market demands and maintain competitiveness.

The cost of bringing an idea to life in product development depends on various factors, including the complexity of the product, materials, manufacturing processes, and scale of production. Additionally, expenses such as prototyping, tooling, testing, and regulatory compliance must be considered. Collaborating with experienced manufacturing sourcing partners who can provide accurate cost estimations and guidance throughout the development process is essential for budget planning and successful product realization.

This is what sets us apart from other firms. We have established partnerships with many different factories overseas as well as within the US. We take all difficulty out of finding a factory to work with. Our partners have signed NDA agreements so your idea is safe throughout the entire process of working with us. If your product requires specialties that our partners do not have, we can also source a new factory to work with that can fulfill what you need to deliver your final product.

Are you an inventor with a groundbreaking idea, but unsure of how to turn it into a reality? Look no further! Our product development firm specializes in partnering with inventors like you to bring innovative concepts to market.

Let us be your trusted partner in transforming your vision into a tangible product that revolutionizes the market. Contact us today to schedule a consultation and take the first step towards making your idea a success!

Thank you for showing interest in Lime Design, you can fill out the contact form below and tell us a little about your project and we will contact you to setup a discovery meeting to give you an accurate quote.

Upon completing this form you will be emailed an NDA (mutual non-disclosure agreement), please sign it as soon as you can.

English, Spanish, Portuguese

Copyright @ 2008-2023 | All Rights Reserved | Terms & Conditions

English, Spanish, Portuguese

Copyright @ 2008-2023 | All Rights Reserved | Terms & Conditions