At Lime Design, we use cutting-edge 3D scanning technology to help our clients bring their ideas to life. The Artec Eva and Artec Spider 3D scanners play a crucial role in this process. These scanners capture highly detailed digital models of objects, which we use to create accurate prototypes and designs. Whether we’re working on product development or reverse engineering, these scanners provide the precision needed for every project.

These scanners also help us reduce the time required for manual measurements and data capturing. The ability to create real-time digital models allows us to visualize concepts faster. This enables quicker decision-making and more effective communication with our clients. At Lime Design, using the Artec Eva and Spider ensures our clients receive the best in 3D scanning technology for their projects.

What is an Artec 3D scanner?

Artec 3D scanners are handheld devices that capture detailed 3D images of objects or environments. These scanners use structured light technology to scan objects without physical contact. Artec 3D scanners are widely used in various industries, from product design to healthcare and reverse engineering. Their ease of use and precision make them a valuable tool for professionals looking to create highly accurate digital models.

Artec scanners are known for their versatility. They work well for small objects and larger scenes, ensuring that no detail gets overlooked during the scanning process.

How do the Artec 3D scanners work?

Artec 3D scanners use structured light to capture the shape and texture of an object. When scanning, the device projects a pattern of light onto the object. This light pattern deforms according to the surface geometry of the scanned object. The scanner’s cameras then capture these deformations, creating a 3D model.

The scanning process is non-invasive, meaning it doesn’t harm the object. Users move the scanner around the object, capturing data from various angles. The scanner automatically stitches these images together to form a complete digital model. Each frame taken contains thousands of data points, contributing to the detailed accuracy of the final model.

Using 3D scanners like the Artec Eva or Spider reduces time and effort. Traditional methods of capturing physical data often require manual measurements and reconstruction, but with Artec scanners, users achieve faster results with better precision.

What is the technology behind the Artec Eva?

Artec 3D scanners are handheld devices that capture detailed 3D images of objects or environments. These scanners use structured light technology to scan objects without physical contact. Artec 3D scanners are widely used in various industries, from product design to healthcare and reverse engineering. Their ease of use and precision make them a valuable tool for professionals looking to create highly accurate digital models.

What can they scan?

Artec scanners can scan a wide range of objects, regardless of size or texture. The devices are designed to capture intricate details while ensuring high accuracy. This makes them ideal for professionals needing precision, such as engineers, designers, and medical practitioners.

Artec scanners are known for their versatility. They work well for small objects and larger scenes, ensuring that no detail gets overlooked during the scanning process.

What is the technology behind the Artec Spider?

The Artec Spider is designed for scanning smaller objects and intricate details. It uses blue light technology, which offers higher precision than white light in capturing fine details. The Spider excels in scanning small objects with complex geometries, such as circuit boards or jewelry.

Artec Spider’s 3D point accuracy is up to 0.05 mm, making it one of the most accurate handheld scanners available. Like the Eva, the Spider captures up to 7.5 frames per second and builds real-time models on the screen. The Spider’s high-resolution capabilities make it an excellent choice for reverse engineering, quality control, and any project requiring high precision.

The Spider’s small field of view allows it to capture intricate geometries that might be missed by scanners designed for larger objects. Its blue light technology reduces interference from surrounding light, ensuring accurate results even in challenging environments.

Eva vs. Spider

The Artec Eva and Artec Spider serve different purposes, though both are exceptional in their respective categories. The Eva is designed for scanning medium to large objects. It is best for projects requiring fast, high-quality scans but does not need extreme detail on small surfaces. Its 3D point accuracy of 0.1 mm makes it effective for general applications.

On the other hand, the Spider focuses on high detail and precision for small objects. With its blue light technology and accuracy of 0.05 mm, the Spider is the better choice for small, intricate items or projects where minute details are critical. The Spider works best for projects requiring precision at the micro level, such as scanning small mechanical parts, jewelry, or dental prosthetics.

What is the best 3D scanner for reverse engineering?

Reverse engineering requires high accuracy and the ability to capture complex geometries. Both the Artec Eva and Spider are suited for reverse engineering, but the Spider tends to perform better for intricate parts. The Spider’s 0.05 mm accuracy ensures even the smallest details are captured, making it ideal for creating digital models of intricate mechanical parts or components.

For larger objects, the Artec Eva is still an excellent choice for reverse engineering. It captures larger areas quickly and efficiently, making it possible to create detailed digital models of automotive parts, large machinery, or even entire environments. Combining the Eva’s speed with the Spider’s precision can offer the best of both worlds for reverse engineering projects.

Ultimately, the best scanner for reverse engineering depends on the specific needs of the project. The Spider excels with small, detailed objects, while the Eva shines when scanning larger items with a broader focus.

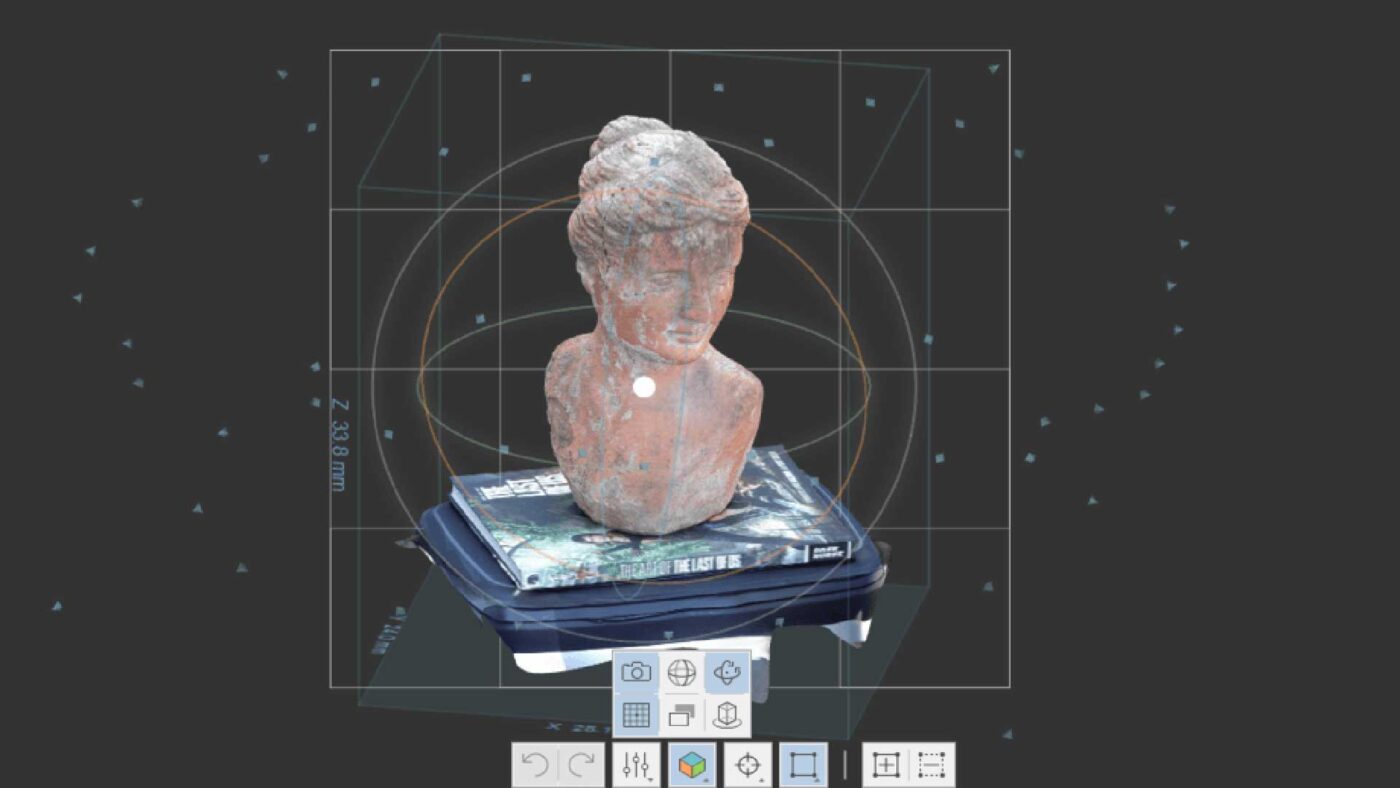

The Artec 3D software

Artec Studio is the software used with Artec 3D scanners. It plays a critical role in converting scanned data into accurate 3D models. The software uses advanced algorithms to process the captured images and stitch them together into a unified model. Artec Studio also includes powerful post-processing tools that allow users to refine their models further.

The software is user-friendly, with a range of features designed to simplify the scanning process. Artec Studio includes automatic alignment, noise filtering, and mesh simplification tools. These features make it easier to create accurate 3D models without needing extensive technical knowledge.

3D software formats

Artec Studio is also compatible with various file formats, making it easy to integrate scanned data into other CAD programs or 3D modeling software. This flexibility makes Artec scanners and software highly versatile tools for industries ranging from design to engineering and healthcare.

In summary, Artec 3D scanners are highly effective tools for capturing detailed, accurate digital models of objects. The Artec Eva and Spider offer different benefits depending on the needs of the project, with the Eva excelling in speed and broad scanning, while the Spider focuses on precision and fine details. The combination of these devices with Artec’s software ensures high-quality results across a range of applications, from reverse engineering to product design.

Conclusion

The Artec Eva and Artec Spider 3D scanners provide incredible versatility and precision for a range of applications. Whether you need to scan large objects or capture intricate details, these scanners deliver. Their technology makes it easy to create accurate digital models, saving time and effort in product development.

The Eva excels in speed and efficiency, scanning medium to large objects quickly and with high accuracy. It’s perfect for projects that require broad scans, such as automotive parts or larger prototypes. Meanwhile, the Spider offers exceptional precision for small objects, capturing intricate geometries with stunning detail. This makes it ideal for tasks like reverse engineering and scanning complex mechanical parts.

Final Thoughts

Choosing between the Eva and Spider depends on your project’s specific needs. If you need speed and coverage, the Eva is a solid choice. For detailed, complex objects, the Spider delivers unmatched precision. Regardless of the application, both scanners offer professional-level performance.

For any industry requiring accuracy and flexibility, the Artec 3D scanners are a powerful solution. These devices help streamline workflows, reduce manual labor, and improve overall project outcomes. By leveraging the strengths of the Eva and Spider, users can confidently take on even the most challenging projects with ease.

Lime Design's Approach to Perfecting Product Development

In the realm of product development, there is an art to embracing failure as a catalyst for growth and improvement. Lime Design, a leading product development firm, has mastered the art of failing forward, using it as a powerful tool to uncover and refine imperfections in the journey of bringing an inventor’s idea to life. By understanding the value of iteration and actively seeking out failures, Lime Design’s team is able to transform setbacks into stepping stones towards creating exceptional products. In this blog, we delve into Lime Design’s unique approach and how they harness the art of failing forward to perfect the development process.

Your idea, our expertise—Together we can create! Stop going it alone in the product development journey. Our team will guide you from start to finish, ensuring your success. Let’s talk today!