At Lime Design, we use 3D scanning to enhance the accuracy and efficiency of our client projects. 3D scanning allows us to capture precise measurements of physical objects. This technology is essential for creating detailed, accurate 3D models for product development. Our team uses 3D scanning to reverse engineer existing products and streamline prototyping. By scanning complex shapes and surfaces, we reduce design time and minimize errors. 3D scanning also helps us modify existing designs or create custom parts. This cutting-edge technology provides our clients with faster, more cost-effective solutions for their projects.

What is a 3D Scanner?

A 3D scanner is a device that captures the shape and dimensions of an object by using light, lasers, or other sensors. It creates a digital representation, allowing you to replicate or analyze physical objects with precision. This scanning process results in a 3D model, which can be used in product development, reverse engineering, and quality control. The machines vary in size and function, from handheld devices to large industrial machines. They provide an efficient way to digitize physical objects.

How does it work?

3D scanning works by collecting data points from an object’s surface, creating a digital mesh or point cloud. The process involves capturing the object’s shape through non-contact methods such as laser triangulation, structured light, or photogrammetry. Laser triangulation projects a beam of light onto the object, and the scanner measures the distance between the light and the object to map its surface.

Structured light scanning projects patterns of light and records how these patterns distort when hitting the object’s surface. This technique captures intricate details and works well with more complex shapes. Photogrammetry, on the other hand, takes multiple photos from different angles, and specialized software combines them into a detailed 3D model.

After the data is captured, the scanner’s software processes it into a usable format. The 3D model can be exported in various file types for use in CAD software, 3D printing, or further manipulation. With precise measurements and detailed features, 3D scanning provides a highly accurate digital replica of the physical object.

What are the benefits?

The benefits extend across many industries. One of the biggest advantages is accuracy. 3D scanners can capture intricate details, down to tiny imperfections. This level of precision is essential in fields like engineering and manufacturing, where errors can be costly.

Speed is another benefit. Traditional measuring methods can take hours, especially when dealing with complex shapes. 3D scanning can complete the same task in minutes, making it a faster option for capturing accurate data. This speed makes 3D scanning an excellent choice for companies offering 3D scanning services in South Florida and beyond.

What Industries use it?

3D scanning also enables quick prototyping. Engineers and designers can turn digital scans into 3D prints, expediting the development process. Scanning an existing object also helps reverse engineering, allowing users to recreate or improve upon existing designs.

For industries like healthcare, 3D scanning offers customized solutions. It can scan a patient’s body for prosthetics or orthodontics, ensuring a perfect fit.

Lastly, scanning saves time and money by reducing the need for manual measurement. By using 3D scanning, companies in South Florida and beyond can minimize human error, lowering overall costs and improving product quality.

What is 3D scanning clean up?

3D scanning cleanup refers to the process of refining and optimizing the raw scan data for use. When you first scan an object, the resulting data may contain noise, holes, or artifacts. These imperfections happen due to surface reflections, shadows, or difficult-to-scan materials.

The first step in cleaning up a 3D scan is removing noise. This involves eliminating unwanted points or data that don’t represent the actual object. The software filters out outliers, which can distort the final 3D model. Next, you may need to fill in any holes or gaps. These gaps occur when parts of the object were not properly captured during scanning, usually because of angles or material transparency. Advanced software tools can automatically fill these gaps by extrapolating data from surrounding areas.

The final step is smoothing and refining the model’s surface. The raw scan might have rough edges or uneven surfaces, which you can correct by applying smoothing algorithms. Once cleaned up, the 3D model is ready for further use in design, prototyping, or analysis.

What industries see a large demand for 3D scanning services?

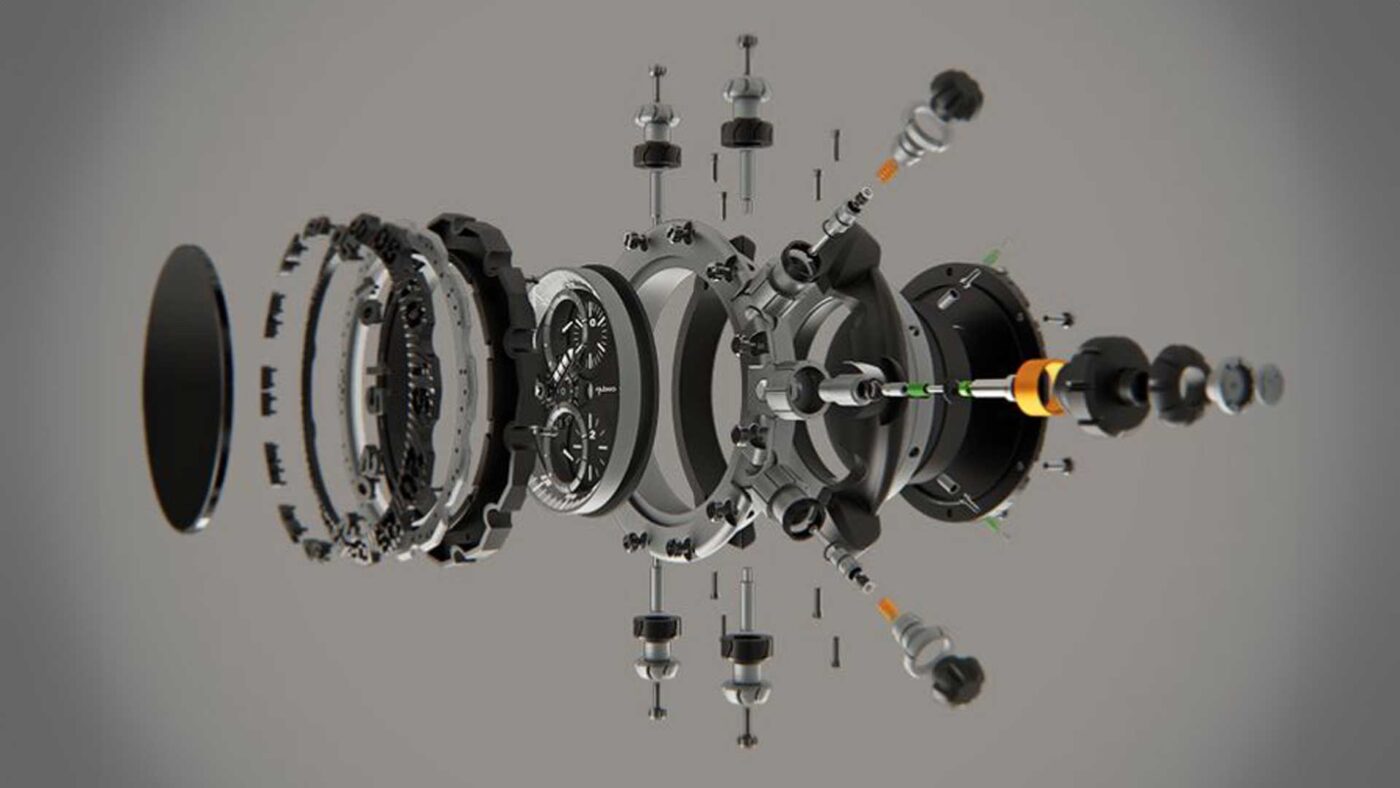

Several industries rely heavily on scanning services. Manufacturing and engineering have a particularly high demand, using 3D scanning for quality control, reverse engineering, and rapid prototyping. By capturing the exact dimensions of parts, manufacturers ensure precision and detect any defects in products before they go to market.

Architecture and construction firms use 3D scanning for site analysis and building documentation. Scanning technology allows them to measure existing structures, ensuring accuracy when adding new features or retrofitting older buildings.

The healthcare industry benefits from 3D scanning in areas such as prosthetics and medical device design. Custom prosthetics are made more efficiently using detailed scans of a patient’s anatomy. Dentistry, too, uses 3D scanning to create perfectly fitting dental appliances like crowns, bridges, and aligners.

How about the Art and Automotive Industry?

In art and cultural heritage preservation, 3D scanning helps capture and protect the details of sculptures, artifacts, and historical buildings. Digital models can be preserved or even used to recreate artifacts that might be lost to damage or time.

Finally, the automotive and aerospace industries use 3D scanning to ensure high-precision parts and components. These industries require tight tolerances, and 3D scanning provides the accuracy needed for safe and effective vehicle production.

How much does it cost?

The cost of 3D scanning varies depending on several factors. The size of the object being scanned is a major consideration. Larger objects take longer to scan and require more processing power, increasing the overall cost. Complexity also matters. Scanning a simple geometric shape will be less expensive than scanning an object with intricate details or moving parts.

The type of scanner used also affects the price. High-end scanners, like those used for industrial purposes, tend to cost more due to their advanced capabilities and precision. In contrast, smaller, less sophisticated scanners can handle simpler tasks at a lower cost.

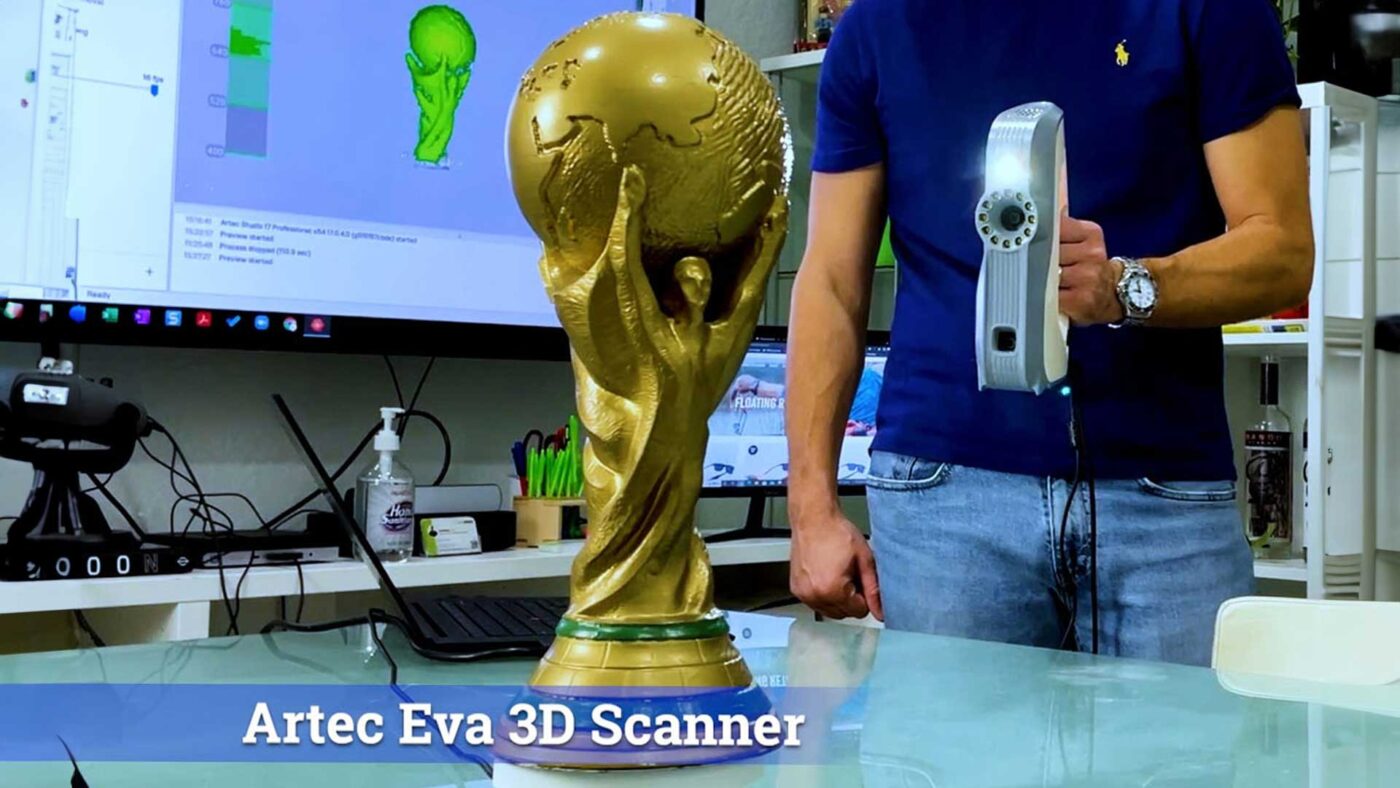

When it comes to our 3D printing machines, we use machines from Artec. One of the machines we have is the Artec Eva. The Artec Eva is ideal for fast, accurate 3D scanning of medium-sized objects. It captures detailed textures and geometric data quickly. For more complex, intricate projects, we use the Artec Spider. The Spider excels at capturing fine details with higher precision, especially on smaller objects. The Artec Eva costs around $19,800, while the Spider is priced at approximately $27,600.

What is a good price for 3D scanning services?

A good price for 3D scanning services largely depends on the complexity of the object being scanned. Simpler objects with smooth surfaces are easier and quicker to scan. These types of projects typically require less time, resulting in a more affordable service. However, as objects become more intricate, the scanning process requires more precision and care.

Objects with complex geometries or detailed surfaces demand advanced scanning techniques and equipment. These projects take longer to capture accurately due to their complexity. The increased time needed to scan and process these objects will impact the overall cost. More detailed scans usually result in higher prices because of the effort involved.

How much cleanup does it require?

In addition to the scanning process, the cleanup of the 3D model is another critical factor in pricing. Cleanup involves refining the raw scan data to ensure an accurate digital model. This process can take several hours, depending on the complexity of the scan. The more time spent on cleanup, the higher the cost for the service.

Ultimately, the price for 3D scanning services reflects the level of detail and effort needed. Simpler scans require less time and are more affordable, while complex projects take longer and cost more. Clients should consider the object’s complexity and the time needed for both scanning and cleanup when estimating costs. The more intricate the project, the more expensive it will be.

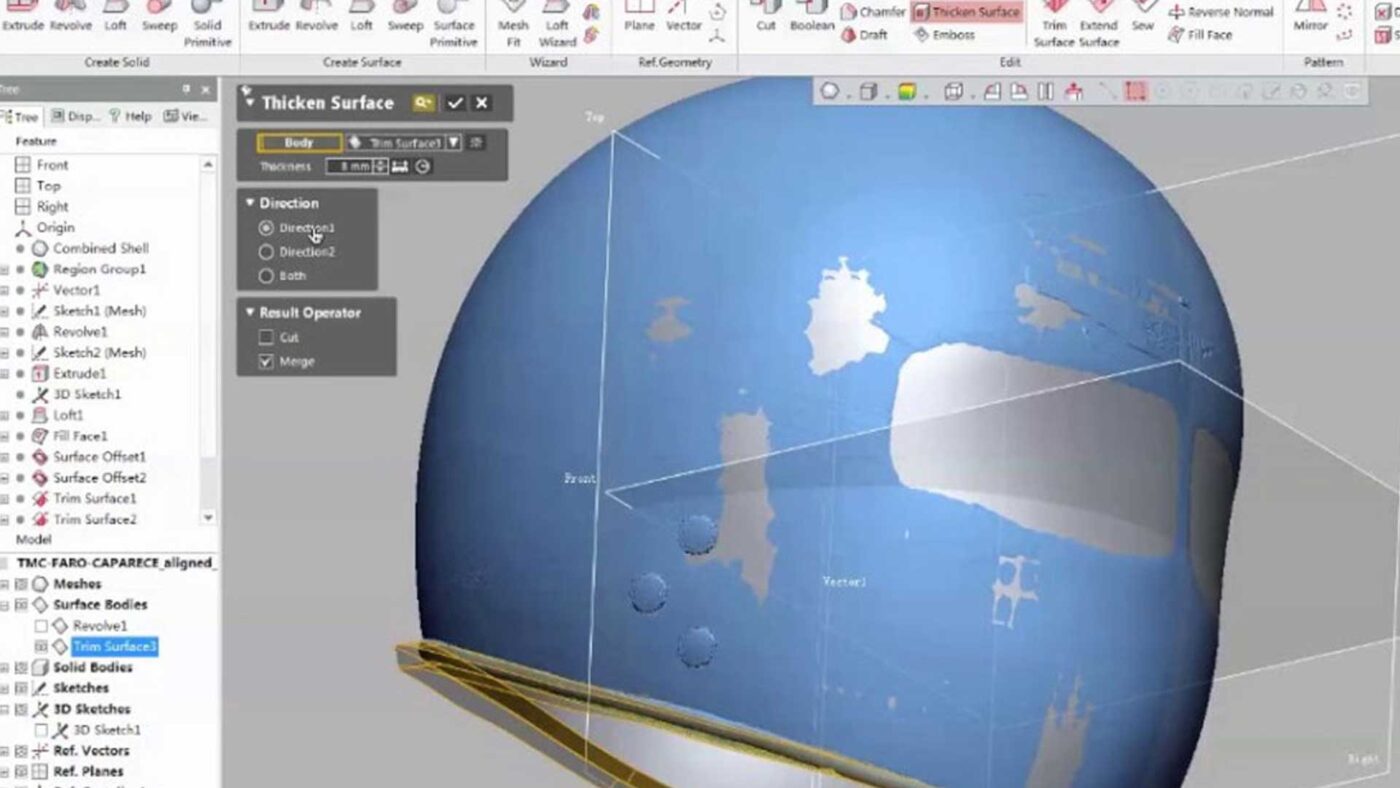

What software do you use?

The software used for 3D scanning is just as important as the scanner itself. It handles the raw data collected during scanning and transforms it into a usable model. Some popular software options include:

- SolidWorks: This sftware is our bread and butter and we often use this for prototyping, engineering, modeling, and more. SolidWorks can handle imported scan data called cloud points that we then take and clean up in order to modify it exactly how we want it.

- Geomagic Design X: Known for its advanced tools in reverse engineering, Geomagic helps create 3D models from scan data with high precision.

- MeshLab: An open-source option for editing and processing 3D meshes. It’s ideal for cleaning up scans and refining surfaces.

- Artec Studio: Designed for Artec 3D scanners, Artec Studio offers powerful algorithms for real-time data processing and model creation.

- Blender: A free and versatile program for 3D modeling and animation. It can process scanned data, though it’s more commonly used in creative industries.

Which software works best?

Choosing the right software depends on the complexity of your project and the level of detail you need. High-end software like Geomagic or Artec Studio will offer more advanced features, but simpler options like MeshLab can handle basic cleanup and processing.

For professionals offering 3D scanning services, the ability to work with different software solutions ensures flexibility.

3D scanning is a vital tool for product development, offering unparalleled accuracy and efficiency. By utilizing our 3D scanning services, you can ensure your project benefits from precise data capture and quick turnaround times. Whether you’re looking to reverse engineer a product, prototype a new design, or enhance quality control, we have the expertise and technology to help.

We do 3D Scanning best!

Our team is equipped to handle complex projects, ensuring that your 3D models are clean, accurate, and ready for use. We take care of the entire process, from scanning to cleanup, so you can focus on what matters most—developing your product. With our advanced 3D scanning equipment and experienced staff, we can tackle even the most challenging objects and deliver exceptional results.

Partnering with us for your 3D scanning needs means faster, more accurate results, ultimately saving you time and resources. Let us support your next product development project with our professional 3D scanning services.

Lime Design's Approach to Perfecting Product Development

In the realm of product development, there is an art to embracing failure as a catalyst for growth and improvement. Lime Design, a leading product development firm, has mastered the art of failing forward, using it as a powerful tool to uncover and refine imperfections in the journey of bringing an inventor’s idea to life. By understanding the value of iteration and actively seeking out failures, Lime Design’s team is able to transform setbacks into stepping stones towards creating exceptional products. In this blog, we delve into Lime Design’s unique approach and how they harness the art of failing forward to perfect the development process.

Bring your product idea to life! Avoid the common pitfalls of designing and manufacturing alone. Let our team help you every step of the way. Contact us now and let’s build something great together!