Ok, so you’re wondering what a physical prototype is or why it is essential. That’s what we’re going to talk about today.

A product prototype is the first version or test version of a product. You’ve probably seen a prototype before. The material or way the prototype gets created depends on what you want to test.

For example, if you want to test its dimensions, only the physical space will need to be tested to ensure all the parts aren’t too big or too small. This type of prototype will probably be hollow and not functional.

Types Of Physical Prototypes

Usually, most types of prototypes break down into two categories. So, Prototypes are either used to test functionality or test aesthetics.

Aesthetic Prototypes

Aesthetic prototypes are what they sound like. It is testing the product’s looks. Dimensions, ergonomics, and visual design. These prototypes can be helpful for presentations or photos since they’re built to look “pretty.”

Functionality Prototypes

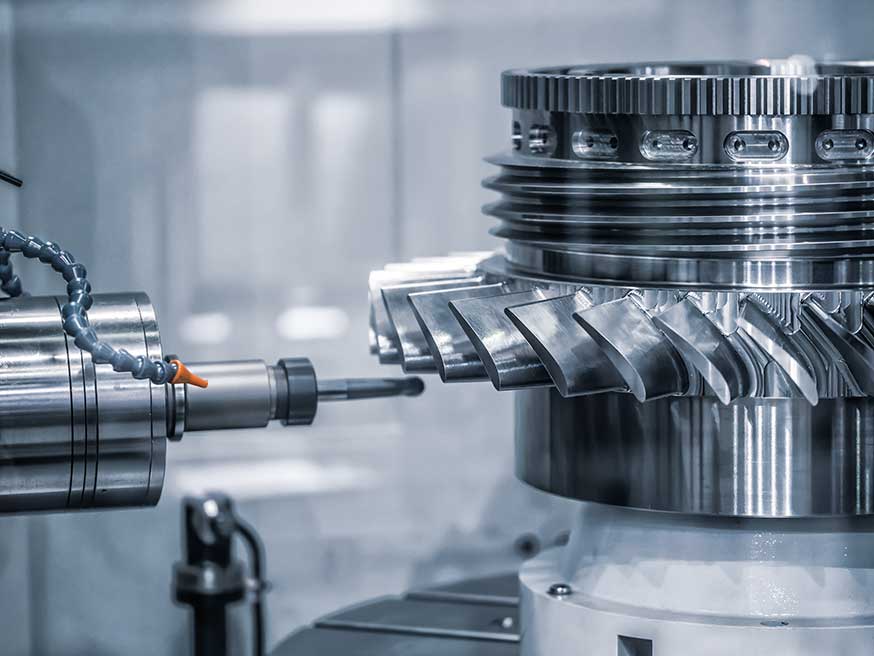

Image credits https://elements.envato.com/machine-for-sewing-K2U5FVG

Functionality-oriented prototypes test mechanisms, durability, reliability, and material strengths. These usually look a bit rougher and “prototype-y” because they are merely used for functionality tests, so appearance isn’t a priority.

Popular Physical Prototyping Methods

There are many methods and processes of creating prototypes. Here are the most popular.

3D Printing

Technology has come a long way in the last two decades. One of the marvelous inventions introduced to the world is 3D Printers. These machines can print any part or full model with many different materials. Some commonly used materials are PLA plastics, silicones, nylons, and many more.

Below are some examples of various items that are 100% 3d printed. Depending on the size, a prototype can be printed in one go or printed into multiple parts and then assembled.

CNC Machining

CNC stands for computer numerical control. This machine is pretty straightforward. To put it into simple terms, it is a maneuverable motorized tool that often sits on a motorized platform controlled by a computer.

CNC machine is an umbrella term for various machines similar to the one above. They can operate on different materials like wood or metals.

Why are prototypes important?

Prototypes are important and necessary in the product development process because they’re the bridging stage between concept and final finished product. Prototypes are useful for testing, Whether it’s functionality or aesthetics. Before manufacturing the final version, the development team uses the prototype to solve all the tweaks and “bugs.”

Another reason prototypes are essential is because you need a prototype to create the final technical specifications, also known as “tech specs.”

A manufacturer needs technical specifications to manufacture a product. Think of these as instruction manuals for anybody looking to manufacture a product. These specifications include material types, dimensions, sizes, densities, and any other details needed to replicate a product perfectly every single time.

How much do product prototypes cost?

Cost is a tricky question to answer because there are so many types of prototypes with different purposes. With this being said, a general functional prototype can range from $5,000 to $30,000. The most significant factors that play into the cost of a prototype are

• Electronics

• Materials

• Overall Size

• Complexity

Electronics

As you can probably imagine, electronics increase the cost of prototypes. In addition, the electronic complexities range from simple electronics, for example, a simple on/off switch, to heavy electronics, for example, a user interface with complex software controlling electronic systems.

Materials

The type of materials can make a difference in the cost. Simple materials such as plastics, woods, and common metals are usually more cost-effective. Compared to exotic materials such as carbon fiber, superalloys, titanium. https://en.wikipedia.org/wiki/Exotic_material

Overall Size

Overall, size is a prominent factor in the cost. How small or big the final product will be. The bigger it is, the more material it requires, and so on.

Complexity

The number of parts and different mechanisms will calculate the complexity of a product. Therefore, the more engineering the development requires, the higher the cost.

How are product prototypes tested?

Image credits https://unsplash.com/photos/AkpJnHXu6Hg

The testing is relative to the environment in which the final product will be used. For example, if it is a product that will be used in a high activity environment, like sports. The testing will revolve around ensuring durability and reliability.

This is done with stress tests like dropping from different heights, applying weights, twisting, and rigidity tests. Other types of tests done are temperature limits and waterproofing.

Who needs physical prototypes?

To understand who needs a prototype, you have to understand that they are used to bridge the gap between concept and finished product. So it can range from a product design team needing a prototype to a manufacturer or Start-up seeking investment.

Product Design Companies

The most common users of physical prototypes are product design firms. They use prototypes to test and improve design concepts. They also use them to bridge the gap between concept and fully manufactured products.

Manufacturers

When initially manufacturing a new product, manufacturers have to test out different materials and manufacturing methods. These first attempts of manufacturing are simply called “manufacturing proof prototypes.” Once an acceptable and efficient prototype is completed by the manufacturer, then full fledge manufacturing will begin.

Start-Ups

When start-ups are first seeking investment for a project or product, they have to approach several investors. It is standard practice to have some sort of prototype to demonstrate your project to the investors. This is where physical or virtual prototypes come in handy.

Bonus Tip for Start-Ups: Don’t approach investors empty-handed and just explain your idea, have something visual or physical they can see.

Where Can I Get A Prototype Made?

Most product development companies are capable of making product prototypes. Depending on the complexity of the product, some companies are capable of working with electronics and software; others can not.

Also, we recommend finding a company that caters to the type of client that you are. For example, some product development companies focus on working with big companies looking to outsource development, and others are geared more towards smaller businesses looking to create products.

Reach Out To Us, we can help make almost any type of prototype. https://limecreativedesign.com/get-quote